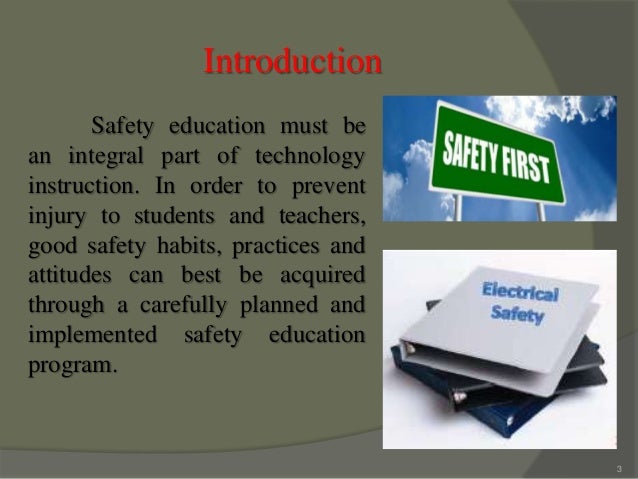

ELECTRICAL SAFETY

Assalamualaikum and have a nice day everyone, today we are given the new task for chapter 7. This group discussion consist of 3 members, Siti Asmadiana binti Saiful Amran , Solehah binti Johari and Nurul Najihah binti Rosli and we are from the Solenoid's group.😁

WHAT IS ELECTRICITY

A form of energy resulting from the existence of charged particles (such as electrons or protons), either statically as an accumulation of charge or dynamically as a current.

-

⇨IMPROPER GROUNDING HAZARD

- Grounding is the process used to eliminate unwanted voltage.

- A ground is a physical electrical connection to the earth

- Electrical equipment must be properly grounded.

- Grounding reduces the risk of being shocked or electrocuted.

- The ground pin safely returns leakage current to ground.

- Never remove the ground pin.

- Removing the ground pin removes an important safety feature.

- You can get shocked!

⇨ OVERLOAD HAZARD

- Overloaded circuits can cause fires.

- Use proper circuit breakers

- Never overload an outlet.

- Do not use power strips or surge protectors on construction sites.

- Use a 3-way extension with a GFCI instead.

WET CONDITION HAZARD

- Wet conditions are hazardous.

- Damaged insulation increases the hazard.

- Always avoid using tools in wet locations.

- Water increases the risk

of electric shock.

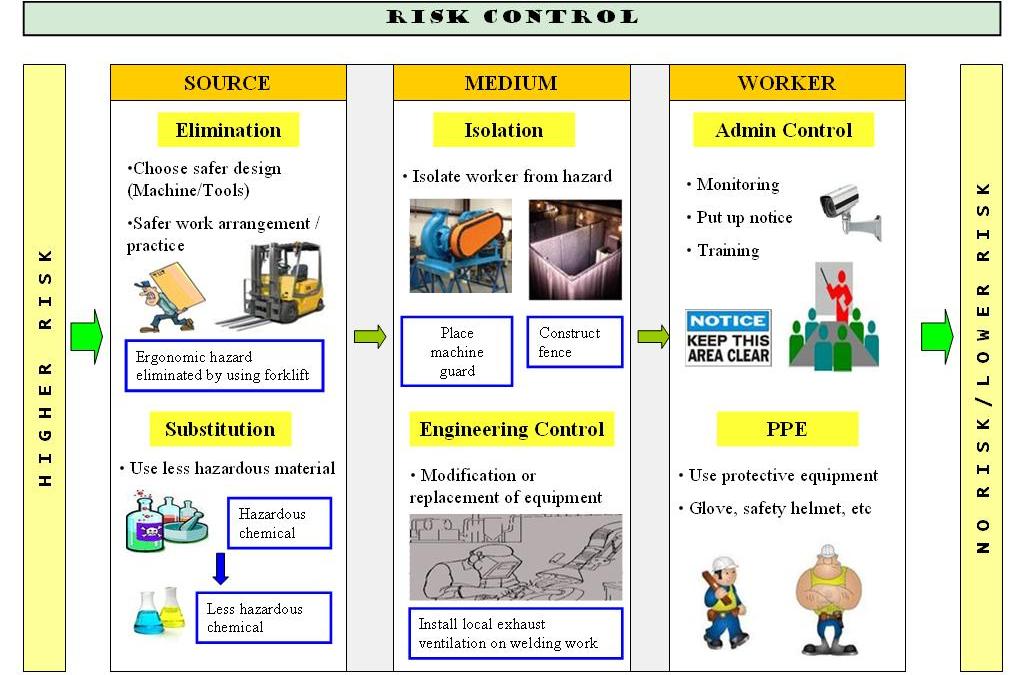

PREVENTING MEASURES IN ELECTRICAL SAFETY

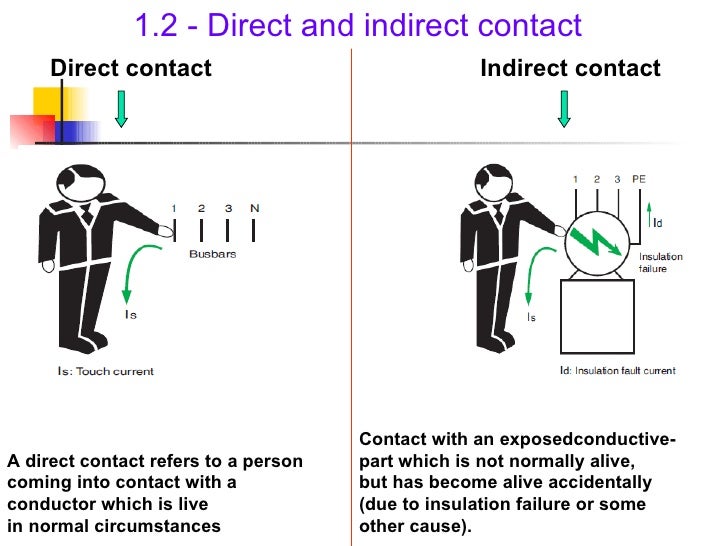

- PROTECTION FROM DIRECT CONTACT

- PROTECTION FROM INDIRECT CONTACT

SAVE WORKING ENVIRONMENT

LOCK OUT AND TAG OUT

- All electrical source

- Place on each disconnecting means used to de-energize circuits

- Attach lock to prevent operating

- Place tag with each lock

OVERLOAD WIRING BY USING THE RIGHT SIZE AND TYPE OF WIRE

- Max.Ampere rating vs size for copper conductor

- value are not more than 3 conductor in raceway or cable

WHAT WILL HAPPEN IF ALL ABOVE IS NOT CONTROL?

- The number of injuries among electrical workers will be increase

There will be no more electrical workers because they to afraid that they will die.

- It will been traumatized for the victims

- Half of their body will been burn and died.

- They also will lose some of their sensation.

Conclusion

•Adequate electrical safety in health-care facilities and systems can be achieved at moderate costs by combining:

1.Good power-distribution system

2.Well designed equipment

3.Periodic maintenance and testing of power systems and equipment

4.Modest training program for medical personnel

REFERENCE

- https://www.lanl.gov/safety/electrical/docs/elec_hazard_awareness_study_guide.pdf

- http://ecmweb.com/content/safety-patrol

- http://www.atlantictraining.com/blog/electrical-safety-training-powerpoints/

- http://www.hobbyprojects.com/electrical-hazards/conclusion-preventing-electrical-hazards.html

- http://www.ece.ucy.ac.cy/courses/ece473x665/slides/8.pdf

.jpg)